Why do we need to vulcanize rubber?

Release Date:2024-01-20 Click:1476

What is the vulcanization mechanism of rubber

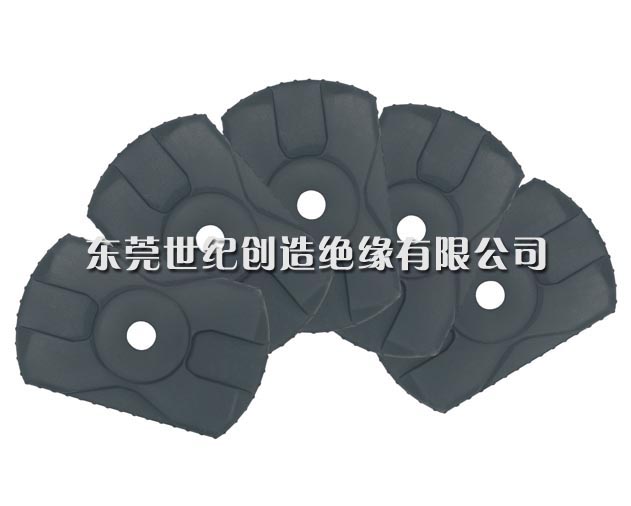

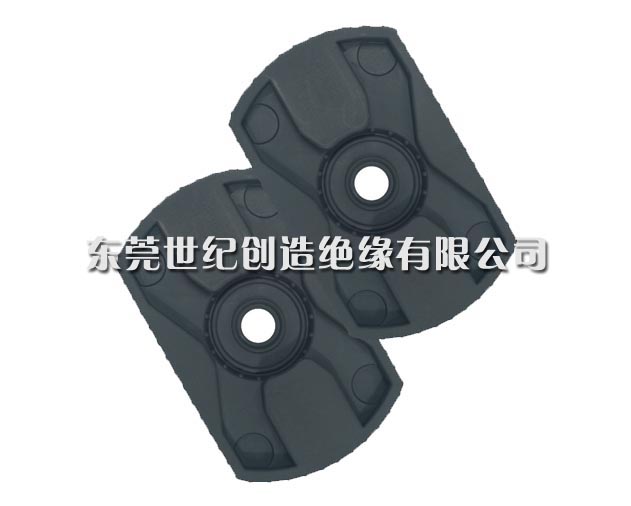

Rubber is a high molecular weight polymer. Through plasticization and mixing, rubber has become short chain small molecules, which can be made into various semi-finished products. Vulcanization is the process of using vulcanizing agents such as sulfur to transform short chain small molecules back into a stable long chain network structure. At this point, the finished product is made and will no longer deform.

Rubber vulcanization, also known as cured rubber or rubber. The general term for rubber materials after vulcanization processing, which have the characteristics of constant viscosity and not easy to break. After vulcanization, a three-dimensional structure is formed inside the rubber, which has high elasticity, heat resistance, tensile strength, and insolubility in organic solvents. The vast majority of rubber products are vulcanized rubber.

When people mention rubber, they naturally associate it with the large and small tires, various rubber hoses, plates, tapes, rings, and many people's rubber shoes, as well as children's favorite rubber toys and balloons. The common feature of all these items is that they have good elasticity. High elasticity is indeed the most important characteristic of rubber, so traditionally, rubber and elastomers have almost become synonymous. The elasticity of rubber increases with increasing temperature, while the opposite is true for general materials.

Rubber releases heat during stretching, while general materials absorb heat; Moreover, unlike general materials, the stress that rubber maintains at a certain elongation increases with increasing temperature. It should be noted that in order for rubber to achieve application performance, it generally requires modification, commonly known as vulcanization. Rubber vulcanization is actually the process of interweaving linear molecules into a network structure, which physically transforms plastic rubber into elastic rubber or hard rubber. This process of change should be broadly referred to as cross-linking. When cross-linked, sulfur plays a bridging and weaving role between macromolecules, just like weaving many single nylon filaments into fishing nets. After vulcanization, the strength, hardness, elasticity, and solvent resistance of rubber undergo significant changes, which is why such rubber has practical value.

Next article:No

Related news:

- Introduction to Rubber Sponge

- The main factors affecting the vulcanization process of rubber

- The principle of rubber foaming and how it is used for listening to voice during mixing in an internal mixer

- How to distinguish the quality of rubber foam strips?

- How rubber foam strips have a shock-absorbing effect

- Selection of Rubber Raw Materials for Rubber Sponge Products

- Why do we need to undergo secondary rubber vulcanization?

- What are the high-temperature resistance characteristics of rubber sponge materials reflected in?

- Common processing methods for sponge rubber foaming

- Why does rubber undergo significant changes in its properties after vulcanization